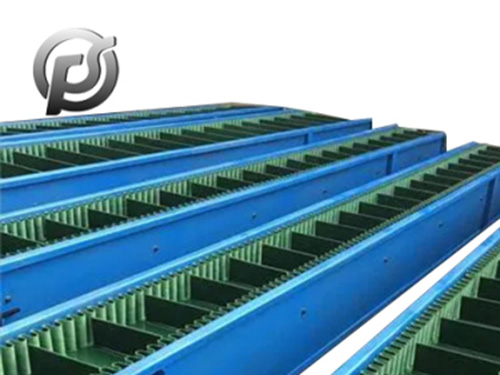

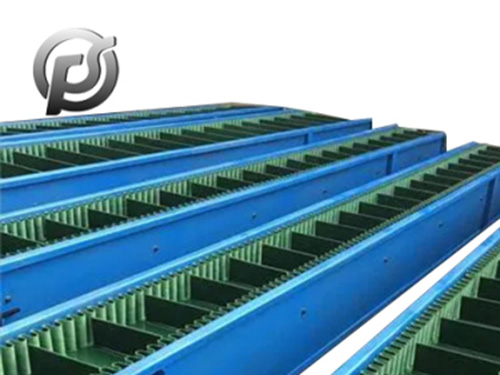

Wear-resistant conveyor belts are indispensable components in various industrial sectors, offering unparalleled durability and reliability in material handling applications. From mining operations to manufacturing facilities, these specialized belts play a crucial role in optimizing efficiency, reducing downtime, and ensuring the smooth flow of materials throughout the production process. Let's explore the significance of wear-resistant conveyor belts and their impact on industrial operations.

One of the primary benefits of

wear-resistant conveyor belts is their ability to withstand the harsh conditions encountered in industrial environments. Whether it's abrasive materials, high temperatures, or heavy loads, these belts are engineered to endure the rigors of daily operation without succumbing to premature wear or damage. This resilience translates into increased uptime and productivity, as maintenance and replacement intervals are minimized, and production continues uninterrupted.

Moreover, wear-resistant conveyor belts contribute to cost savings for industrial operators by reducing the need for frequent maintenance and replacement. Traditional conveyor belts often suffer from excessive wear and tear, leading to costly downtime for repairs and replacements. In contrast, wear-resistant belts offer extended service life and reduced maintenance requirements, resulting in lower operational costs and improved overall efficiency.

Furthermore, wear-resistant conveyor belts enhance workplace safety by minimizing the risk of accidents and injuries associated with conveyor system failures. By maintaining their integrity under challenging conditions, these belts provide a reliable means of transporting materials without the potential for sudden failures or breakdowns. This reliability ensures a safer working environment for employees and reduces the likelihood of costly accidents or incidents.

In addition to their durability and safety benefits, wear-resistant conveyor belts also contribute to environmental sustainability by minimizing waste and resource consumption. Their longer service life and reduced need for replacement mean fewer belts end up in landfills, leading to lower environmental impact and reduced carbon footprint. Additionally, the efficiency gains achieved through improved conveyor performance translate into reduced energy consumption and lower greenhouse gas emissions.

The applications of wear-resistant conveyor belts span a wide range of industries, including mining, agriculture, construction, and recycling. In mining operations, these belts are used to transport heavy loads of ore and minerals, enduring abrasive materials and extreme conditions underground. In agriculture, they facilitate the efficient movement of grains, seeds, and bulk commodities, ensuring timely processing and distribution.

In construction, wear-resistant conveyor belts are essential for transporting materials such as aggregates, concrete, and asphalt during building projects. Their durability and reliability help maintain construction schedules and minimize downtime, ultimately contributing to the timely completion of projects. Additionally, in recycling facilities, these belts play a crucial role in sorting and processing materials for reuse, contributing to waste reduction and resource conservation.

In conclusion, wear-resistant conveyor belts are integral components of industrial operations, providing durability, reliability, and efficiency in material handling applications. With their ability to withstand challenging conditions, reduce maintenance costs, and enhance workplace safety, these belts play a vital role in optimizing productivity and sustainability across diverse industries. As technology continues to advance, wear-resistant conveyor belts will continue to evolve, driving further improvements in industrial efficiency and performance.

PE Conveyor Belts: Characteristics, Applications, and Advantages

PE Conveyor Belts: Characteristics, Applications, and Advantages

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility