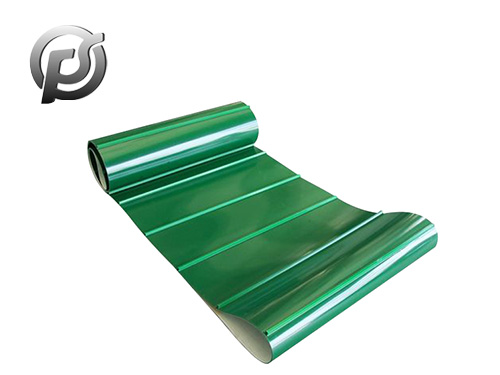

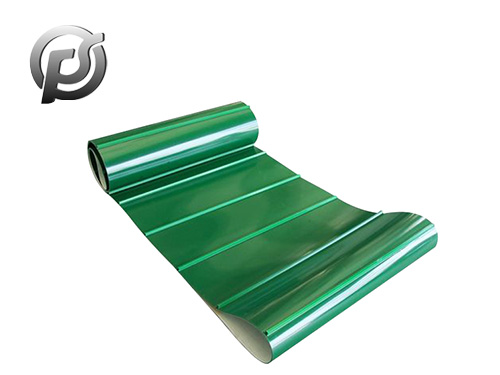

Light conveyor belts, also known as lightweight conveyor belts, offer several advantages in various industrial and commercial applications. Here are some of the key advantages:

Flexibility:

Light conveyor belts are often more flexible than heavy-duty alternatives, making them suitable for applications with curved paths or where flexibility is essential. This flexibility allows for easy installation in tight spaces and complex conveyor systems.

Energy Efficiency:

Due to their lightweight construction, these belts require less power to operate. This can result in energy savings, making them a more energy-efficient option compared to heavier conveyor belts.

Ease of Installation:

Light conveyor belts are typically easier to handle and install than heavier belts. This can lead to reduced installation time and labor costs, especially in situations where the conveyor system may need to be modified or extended.

Reduced Wear and Tear on Equipment:

The lightweight nature of these belts means that they exert less stress on the conveyor system's components, such as rollers and bearings. This can contribute to lower maintenance costs and longer equipment lifespan.

Versatility:

Light conveyor belts are available in a variety of materials, including PVC, PU (polyurethane), and fabric. This versatility allows them to be used in diverse industries and applications, such as food processing, packaging, pharmaceuticals, and manufacturing.

Cost-Effectiveness:

Light conveyor belts are often more cost-effective than heavy-duty alternatives, making them a preferred choice for applications where heavy-duty strength is not required. This can be particularly advantageous for industries with budget constraints.

Chemical Resistance:

Many light conveyor belts are designed to be resistant to chemicals and oils. This makes them suitable for industries where exposure to various substances is common, such as in the chemical and food processing industries.

Low Noise Level:

Light conveyor belts, especially those made of materials like polyurethane, tend to produce less noise during operation compared to heavier belts. This can be advantageous in environments where noise reduction is a consideration.

Customization Options:

Light conveyor belts can be easily customized to meet specific application requirements. This includes variations in material composition, surface patterns, and belt thickness, allowing for tailor-made solutions for different industries.

Hygiene and Cleanability:

Light conveyor belts made from materials like PVC are often chosen for their hygienic properties. They are easy to clean and sanitize, making them suitable for industries where cleanliness and hygiene are critical, such as in food processing.

It's important to note that while light conveyor belts offer these advantages, the choice of a conveyor belt should be based on the specific requirements of the application, including load capacity, operating conditions, and environmental factors.

PE Conveyor Belts: Characteristics, Applications, and Advantages

PE Conveyor Belts: Characteristics, Applications, and Advantages

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility