Certainly,

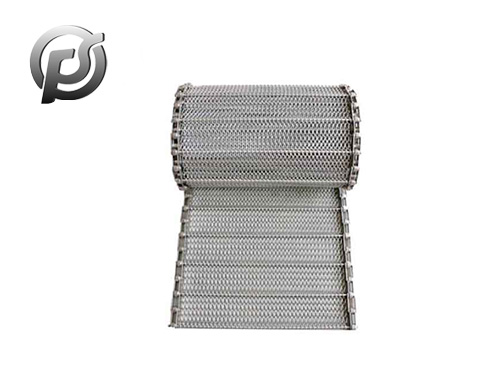

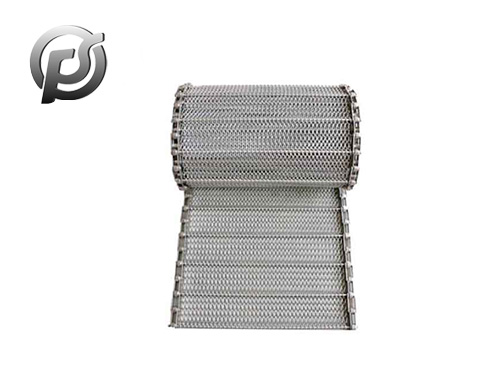

small conveyor belts can significantly improve work quality and speed in various industries and applications. Here are several ways in which small conveyor belts contribute to enhancing efficiency:

Automation and Material Handling:

Small conveyor belts automate the process of moving materials from one location to another, reducing the need for manual handling.

They facilitate the continuous flow of materials, streamlining production and minimizing downtime.

Increased Productivity:

By automating material transport, conveyor belts enable a more efficient workflow, leading to increased productivity.

Workers can focus on other tasks, while the conveyor system handles the movement of materials.

Precision and Consistency:

Conveyor belts provide precise and consistent movement of materials, ensuring accuracy in production processes.

This can lead to higher quality products as variations in manual handling are minimized.

Speed and Throughput:

Conveyor belts operate at consistent speeds, allowing for a faster and more continuous production process.

Increased throughput can be achieved, resulting in higher production rates.

Reduced Labor Costs:

Automation through conveyor belts can reduce the reliance on manual labor for material handling.

This, in turn, can lead to cost savings and a more efficient allocation of human resources.

Customization and Flexibility:

Small conveyor belts are often modular and can be customized to fit specific space and production requirements.

They offer flexibility in terms of configurations, allowing for adaptation to different processes.

Improved Safety:

Automated conveyor systems can contribute to a safer working environment by reducing the need for manual material handling, which may involve heavy lifting and repetitive tasks.

Conveyor systems can be designed with safety features such as emergency stops and guards.

Integration with Other Equipment:

Conveyor belts can be integrated into larger automated systems, connecting various stages of the production line.

This integration improves overall system efficiency and coordination.

Reduced Material Loss:

Conveyor belts can minimize material loss during transport, ensuring that products or materials reach their destination without spillage or waste.

Enhanced Quality Control:

Conveyor systems allow for better control over the movement of materials, facilitating quality checks and inspections at various points along the production line.

In summary, small conveyor belts offer a range of benefits, including increased efficiency, speed, and precision in material handling, leading to improved work quality and overall productivity in various industries.

PE Conveyor Belts: Characteristics, Applications, and Advantages

PE Conveyor Belts: Characteristics, Applications, and Advantages

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility