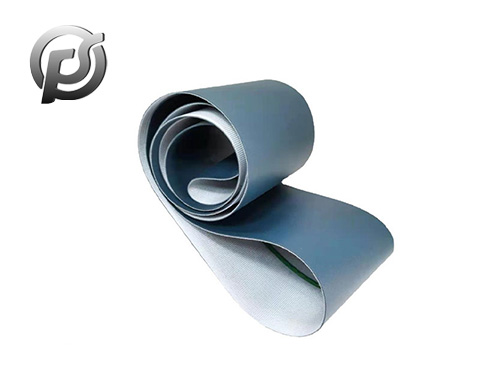

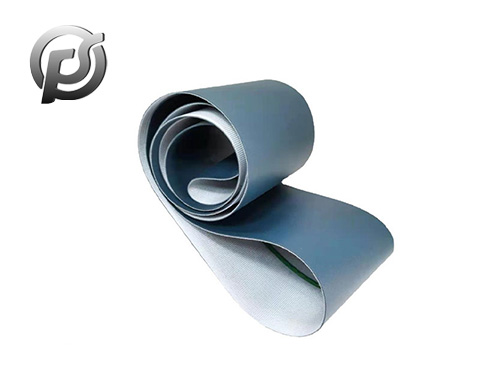

Polyester conveyor belts are a popular choice in material handling industries due to their durability, versatility, and cost-effectiveness. These belts are made from polyester fabric layers coated with various materials to enhance performance and meet specific application requirements.

One of the primary advantages of polyester conveyor belts is their exceptional strength and resistance to abrasion, tearing, and impact. This durability makes them suitable for conveying heavy loads, bulk materials, and sharp-edged components without experiencing premature wear or damage.

Furthermore,

polyester conveyor belts offer excellent dimensional stability, ensuring consistent tracking and alignment during operation. This stability minimizes downtime and maintenance efforts, leading to improved productivity and operational efficiency in industrial settings.

Polyester conveyor belts also exhibit good chemical resistance, making them suitable for handling a wide range of materials including oils, chemicals, and food products. Their resistance to moisture and humidity prevents degradation and ensures reliable performance in challenging environments.

Moreover, polyester conveyor belts are lightweight and flexible, allowing for easy installation, maintenance, and replacement. Their flexibility enables them to conform to pulley systems and conveyor configurations, optimizing material flow and reducing energy consumption.

Additionally, polyester conveyor belts can be customized with different surface textures and profiles to enhance grip, reduce slippage, and facilitate the efficient movement of products. These customization options make them versatile for various industries such as mining, manufacturing, agriculture, food processing, and logistics.

In the mining industry, polyester conveyor belts are used for transporting bulk materials such as ores, coal, and aggregates over long distances, contributing to efficient material handling and logistics. In manufacturing plants, these belts facilitate the movement of raw materials, finished products, and components across production lines, improving workflow and productivity.

In food processing facilities, polyester conveyor belts meet stringent hygiene standards and FDA regulations, making them suitable for conveying food products safely and efficiently. Their smooth surface and easy-clean properties ensure food safety and minimize contamination risks.

In conclusion, polyester conveyor belts offer a range of advantages including durability, dimensional stability, chemical resistance, flexibility, customization options, and suitability for diverse applications in material handling industries. Their reliable performance, cost-effectiveness, and versatility make them a preferred choice for conveyor systems, contributing to streamlined operations and optimized logistics in various sectors.

PE Conveyor Belts: Characteristics, Applications, and Advantages

PE Conveyor Belts: Characteristics, Applications, and Advantages

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility