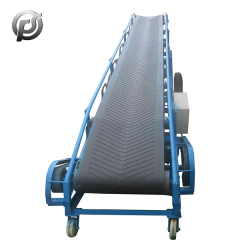

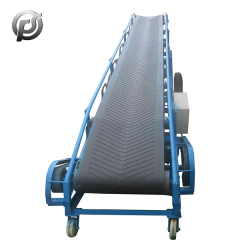

Stone conveyor belts have played a pivotal role in transforming the material handling landscape, particularly in industries where the efficient movement of heavy and abrasive materials is crucial. These specialized conveyor belts are designed to withstand the harsh conditions associated with the transportation of stones, providing a reliable and durable solution for various applications.

The construction of

stone conveyor belts involves a combination of robust materials such as rubber, fabric, and metal components. This composition ensures resistance to wear, tear, and impact, making them suitable for conveying stones of different sizes and weights. The belts feature designs that prevent material spillage and facilitate smooth transport, minimizing downtime and maintenance costs.

In mining and quarrying operations,

stone conveyor belts streamline the process of extracting, transporting, and sorting materials. Their flexibility allows for easy adaptation to different terrains, contributing to increased operational efficiency. Additionally, advancements in technology have led to innovations such as self-cleaning systems and sensors that enhance safety and optimize performance.

Stone conveyor belts find applications in various industries beyond mining, including construction, agriculture, and manufacturing. Their versatility and reliability make them indispensable for operations where a continuous and efficient material flow is paramount.

As industries continue to evolve, the development of stone conveyor belts remains a dynamic field. Ongoing research focuses on improving conveyor belt materials, incorporating smart technologies, and addressing environmental sustainability concerns. The evolution of stone conveyor belts reflects a commitment to advancing material handling systems for increased efficiency and reduced environmental impact.

PE Conveyor Belts: Characteristics, Applications, and Advantages

PE Conveyor Belts: Characteristics, Applications, and Advantages

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility