Grain conveyor belting plays a pivotal role in the agricultural industry by facilitating the seamless and efficient movement of grains within processing facilities. These specialized belts are designed to withstand rigorous conditions while ensuring smooth transportation of grains, contributing significantly to operational efficiency and productivity. In this article, we explore the importance of

grain conveyor belting and how innovative solutions are revolutionizing grain handling processes.

The primary function of grain conveyor belting is to transport bulk quantities of grains such as wheat, corn, soybeans, and rice from one point to another within a grain handling facility. These belts are engineered with durable materials such as rubber, PVC, or nylon to withstand heavy loads, abrasion, and harsh environmental conditions commonly encountered in agricultural operations.

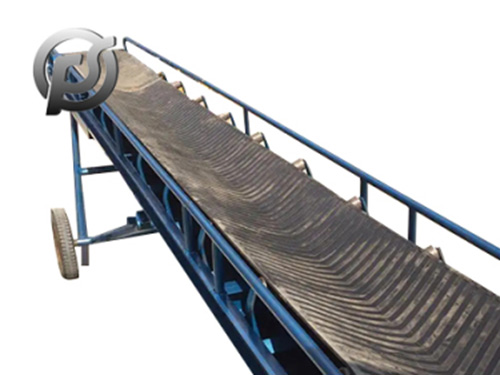

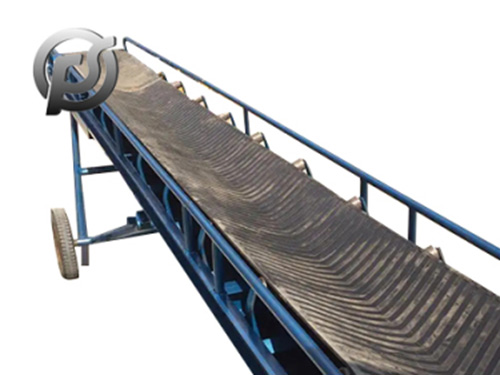

One of the key advantages of modern grain conveyor belting is its ability to minimize spillage and product loss during transportation. Advanced designs incorporate features such as cleats, sidewalls, and V-guides to prevent grains from spilling over or getting stuck, thereby reducing waste and ensuring maximum yield for farmers and processors.

Innovations in grain conveyor belting technology have led to the development of customizable solutions tailored to specific industry requirements. Manufacturers offer a range of belt types, including flat belts for horizontal conveying, inclined belts for elevation changes, and troughed belts for bulk material handling. These options allow businesses to optimize their grain handling systems for enhanced efficiency and throughput.

Moreover, advancements in belt fabrication techniques and materials have resulted in improved durability, longevity, and resistance to wear and tear. This translates to lower maintenance costs, increased uptime, and overall reliability of grain conveyor systems, ultimately benefiting operational bottom lines.

Furthermore, the integration of automation and digital monitoring systems has revolutionized grain conveyor belting operations. Smart sensors, conveyor control systems, and predictive maintenance tools enable real-time monitoring of belt performance, detection of anomalies, and proactive maintenance scheduling, minimizing downtime and optimizing overall system performance.

In conclusion, grain conveyor belting plays a vital role in modern agricultural operations, enabling efficient and reliable transportation of grains throughout processing facilities. With continuous innovation and technological advancements, the future of grain conveyor belting promises even greater efficiency, sustainability, and profitability for the agricultural industry.

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Exploring the Efficiency and Versatility of Light Conveyor Belts

Exploring the Efficiency and Versatility of Light Conveyor Belts