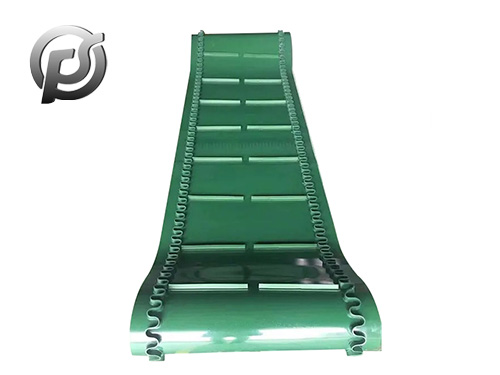

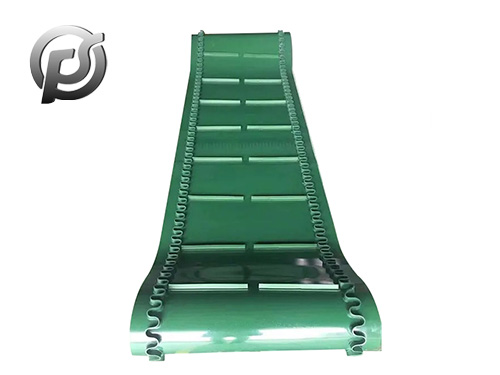

Grains belt conveyors play a pivotal role in the agricultural industry, facilitating the efficient movement of grains from storage facilities to processing plants or distribution centers. These conveyor systems are instrumental in streamlining operations, reducing manual labor, and ensuring the timely delivery of grains. In this article, we explore the functionality and benefits of grains belt conveyor systems in agricultural settings.

1. Streamlined Transportation:

Grains belt conveyors offer a seamless method of transporting bulk quantities of grains over long distances. By utilizing continuous belts powered by motors, these conveyor systems can move grains smoothly and efficiently, minimizing the need for manual handling and reducing the risk of product damage.

2. Versatility and Customization: Grains belt conveyors are highly versatile and can be customized to suit specific operational requirements. Whether transporting wheat, corn, rice, or other grains, conveyor systems can be tailored in terms of belt width, length, speed, and incline to accommodate different types of grains and facility layouts.

3. Enhanced Efficiency: The automation provided by grains belt conveyor systems significantly enhances operational efficiency in grain handling facilities. With consistent and reliable transportation, conveyor systems help optimize workflow processes, reduce turnaround times, and increase overall productivity.

4. Preservation of Grain Quality: Proper handling is crucial for preserving the quality of grains, and belt conveyors excel in this regard. Gentle handling techniques minimize grain damage and prevent contamination, ensuring that grains maintain their integrity and nutritional value throughout the transportation process.

5. Cost-Effective Solution: Grains belt conveyors offer a cost-effective solution for grain transportation compared to traditional methods such as manual labor or truck hauling. With lower labor requirements and reduced maintenance costs, conveyor systems provide a sustainable and economical option for grain handling operations.

6. Safety and Reliability: Modern grains belt conveyor systems are equipped with safety features such as emergency stop switches, guarding, and sensors to prevent accidents and ensure worker safety. Additionally, built-in monitoring systems help detect and address any operational issues promptly, ensuring continuous and reliable operation.

7. Environmental Sustainability: By minimizing the need for fuel-consuming vehicles and reducing carbon emissions associated with grain transportation, belt conveyor systems contribute to environmental sustainability in the agricultural industry. The efficient use of energy and resources makes conveyor systems an eco-friendly choice for grain handling facilities.

In conclusion, grains belt conveyor systems offer a multitude of benefits for the agricultural industry, including streamlined transportation, enhanced efficiency, preservation of grain quality, and cost-effectiveness. By investing in these advanced conveyor technologies, grain handling facilities can optimize their operations, improve productivity, and contribute to a more sustainable future for the agricultural sector.

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Exploring the Efficiency and Versatility of Light Conveyor Belts

Exploring the Efficiency and Versatility of Light Conveyor Belts