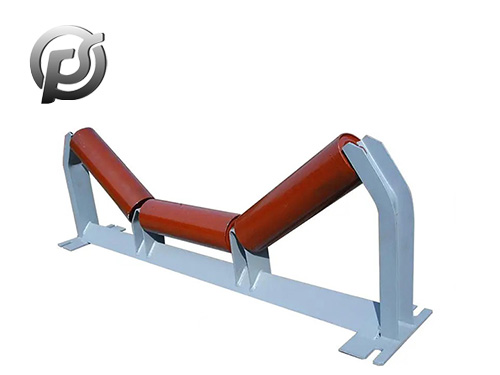

V type belt conveyors have revolutionized material handling systems, providing a seamless and efficient solution for various industries. These specialized conveyors, characterized by their V-shaped profile, offer a range of advantages that contribute to enhanced productivity, reliability, and cost-effectiveness in the transportation of goods.

The unique design of

V type belt conveyors allows for optimal traction and grip, ensuring a secure and stable movement of materials. The V-shaped profile of the belt helps prevent slippage, especially when handling bulk or heavy items. This feature is particularly advantageous in industries such as mining, agriculture, and manufacturing, where the reliable transportation of materials is paramount.

Versatility is a key attribute of

V type belt conveyors, as they can accommodate a wide range of materials, sizes, and shapes. From granular substances to irregularly shaped objects, these conveyors provide a flexible and adaptable solution for diverse material handling needs. The ability to handle various types of loads makes V type belt conveyors suitable for applications in warehouses, distribution centers, and production facilities.

The efficiency of V type belt conveyors extends to their energy-saving capabilities. The reduced friction between the V-shaped belt and the pulleys minimizes energy consumption, contributing to overall operational cost savings. This energy-efficient design aligns with the growing emphasis on sustainable and cost-effective solutions in modern industries.

Maintenance is streamlined with V type belt conveyors, as their design minimizes wear and tear on components. The V-shaped profile distributes the load evenly, reducing stress on the belt and pulleys. This not only extends the lifespan of the conveyor system but also lowers maintenance requirements, leading to increased uptime and operational efficiency.

Furthermore, the V type belt conveyor design allows for inclined or declined transportation of materials. This capability is valuable in scenarios where elevation changes are required, providing a smooth and controlled transport process. Industries such as agriculture and mining benefit from this feature, optimizing the flow of materials in various operational settings.

In conclusion, V type belt conveyors represent a pivotal innovation in material handling, combining efficiency, versatility, and energy savings. Their reliable performance and adaptability make them a cornerstone in modern industries seeking streamlined and cost-effective solutions for material transportation. As industries evolve, the prominence of V type belt conveyors is set to grow, contributing to the advancement of material handling systems globally.

PE Conveyor Belts: Characteristics, Applications, and Advantages

PE Conveyor Belts: Characteristics, Applications, and Advantages

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Stone Conveyor Belt: Enhancing Efficiency and Productivity in Material Handling

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility

Optimizing Operations with PE Conveyor Belts: Durability, Efficiency, and Versatility