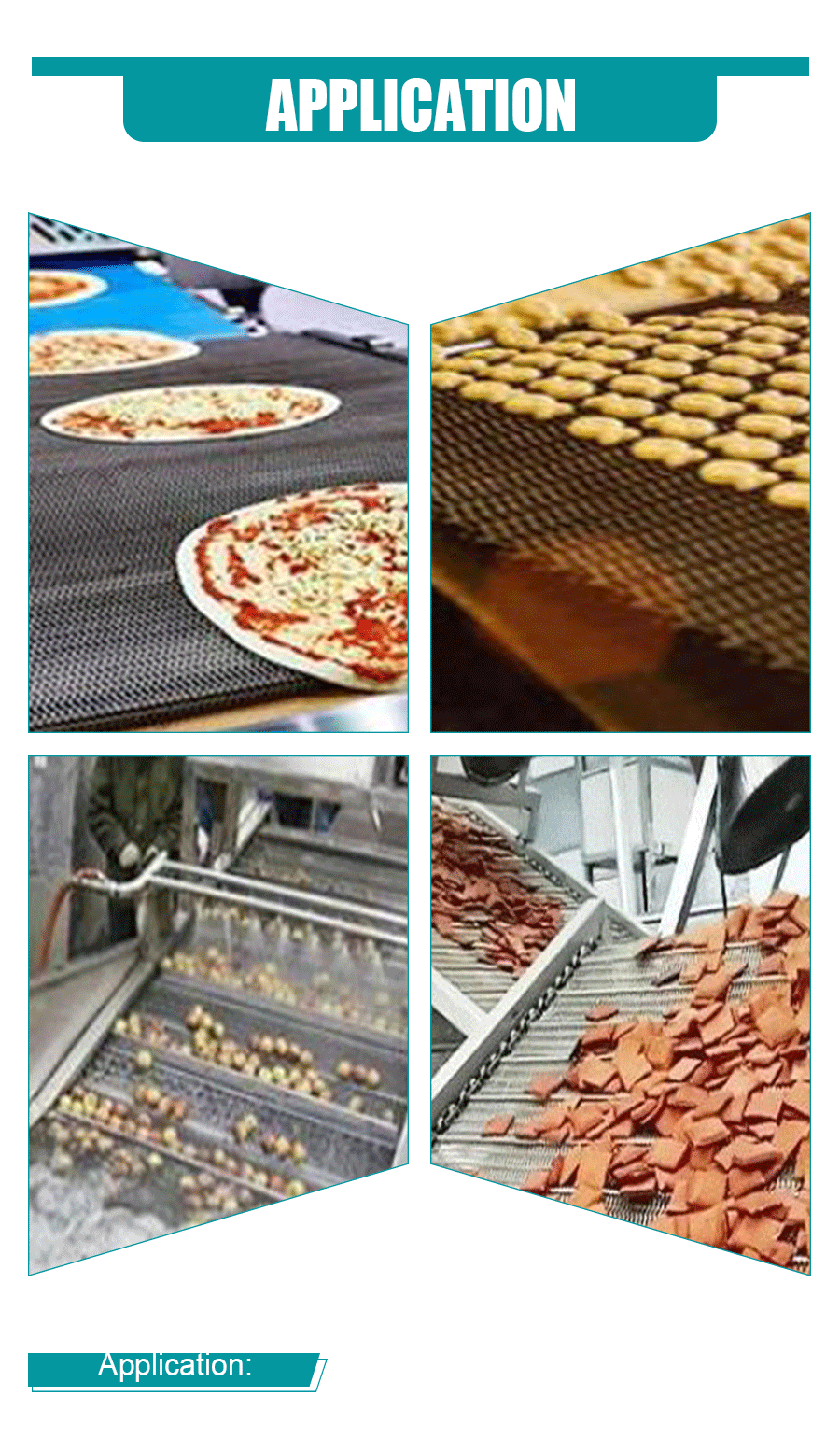

Stainless steel conveyor belt adopts stainless steel plate stamping molding, chain drive, each section is connected by 6-10mm support rod, its smooth movement, large strength, suitable for conveying small high-density objects, smooth operation in the process of conveying, easy to install and replace, high cost, long service life. Widely used in glass products industry, food processing industry, dehydrated vegetables, frozen food and other products transport.

Stainless steel conveyor belt adopts stainless steel plate stamping molding, chain drive, each section is connected by 6-10mm support rod, its smooth movement, large strength, suitable for conveying small high-density objects, smooth operation in the process of conveying, easy to install and replace, high cost, long service life. Widely used in glass products industry, food processing industry, dehydrated vegetables, frozen food and other products transport.|

Net belt material selection reference |

||||||||

|

Type Of Steel |

||||||||

|

C |

Si |

Mn |

Ni |

Cr |

Mo |

|||

|

1Cr13 |

≤0.15 |

≤0.6 |

≤0.6 |

/ |

12-14 |

/ |

650℃ |

Ordinary mesh belt |

|

1Cr17 |

≤0.15 |

≤0.6 |

≤0.6 |

/ |

12-18 |

/ |

650℃ |

Ordinary mesh belt |

|

304 |

≤0.06 |

≤1.0 |

≤0.6 |

8.9-10 |

18-20 |

/ |

920℃ |

Ordinary mesh belt |

|

304L |

≤0.03 |

≤1.0 |

≤0.6 |

9-13 |

18-20 |

/ |

920℃ |

Grain boundary corrosion resistance |

|

316 |

≤0.08 |

≤1.0 |

≤0.6 |

10-14 |

16-18 |

2-3 |

920℃ |

|

|

316L |

≤0.03 |

≤1.0 |

≤0.6 |

12-15 |

16-18 |

2-3 |

920℃ |

Grain boundary corrosion resistance |

|

309S |

≤0.08 |

≤1.0 |

≤0.6 |

12-15 |

22-14 |

/ |

1000℃ |

Long time high temperature resistance |

|

310S |

≤0.08 |

≤1.5 |

≤0.6 |

19-22 |

24-26 |

/ |

1100℃ |

High temperature and high temperature shock resistance High temperature cycle |

|

314 |

≤0.25 |

1.5-3.0 |

≤0.6 |

19-22 |

23-26 |

/ |

1200℃ |

Improves antioxidant properties based on 310 |

|

Cr20Ni80 |

≤0.15 |

0.4-1.3 |

≤0.6 |

72-78 |

20-23 |

/ |

1200℃ |

High temperature and oxidation resistance |

|

Special specifications can also be produced according to customer requirements |

||||||||

|

Comparison table of common specifications of chain mesh belt(mm) |

|||||

|

Width |

Wire diameter |

Pitch |

Thread pitch |

Chain pitch |

String of stem diameter |

|

200-300 |

1.0-1.5 |

6-20 |

3-20 |

25.4 |

6 |

|

200-300 |

1.5-2.0 |

10-30 |

8-20 |

31.75 |

8 |

|

400-500 |

1.0-1.5 |

6-20 |

3-20 |

25.4 |

6 |

|

400-500 |

1.5-2.0 |

10-40 |

8-30 |

31.75 |

8 |

|

600-800 |

1.0-1.5 |

6-20 |

3-20 |

31.75 |

8 |

|

600-800 |

1.5-2.0 |

10-30 |

8-30 |

31.75-38.1 |

6-8 |

|

900-1000 |

1.0-1.5 |

6-20 |

3-20 |

38.1-50.8 |

8-10 |

|

900-1000 |

1.5-2.0 |

10-40 |

8-40 |

38.1-50.8 |

10-12 |

|

1100-1500 |

1.0-1.5 |

6-20 |

3-20 |

38.1-50.8 |

10-12 |

|

1100-1500 |

1.5-2.0 |

10-50 |

8-40 |

38.1-50.8 |

10-14 |

|

1100-1500 |

2.0-3.0 |

20-60 |

15-50 |

38.1-50.8 |

10-14 |

|

1600-4000 |

1.0-1.5 |

6-20 |

3-20 |

38.1-50.8 |

10-14 |

|

1600-4000 |

1.5-2.0 |

10-50 |

8-40 |

38.1-50.8 |

10-14 |

|

1600-4000 |

2.0-3.0 |

20-60 |

15-50 |

38.1-50.8 |

10-14 |