The automatic control and computer management system are the control and command center of the whole Automated sortation, and all the actions of each part of the sorting system are decided by the control system. Its role is to identify, receive and process the sorting signal, according to the sorting signal classification institutions according to certain rules (such as variety, location, etc.) automatic classification of products, so as to determine the flow of products. The source of sorting signal can be obtained by barcode scanning, color code scanning, keyboard input, quality detection, voice recognition, height detection and shape recognition, etc. After information processing, it can be converted into the corresponding picking sheet, warehousing sheet or electronic picking signal, automatic sorting operation.

The automatic identification device is the basic system for automated sortation of materials. In the logistics distribution center, the widely used automatic identification system is bar code system and radio frequency system. Bar code automatic identification system of the photoelectric scanning installed in different locations of the sorting machine, when the material in the visible range scanner, automatic reading material on the bar code information, through the code of software can be translated into the barcode material information, at the same time perception material location information on the sorting machine, the automatic transmission to the background computer management information system.

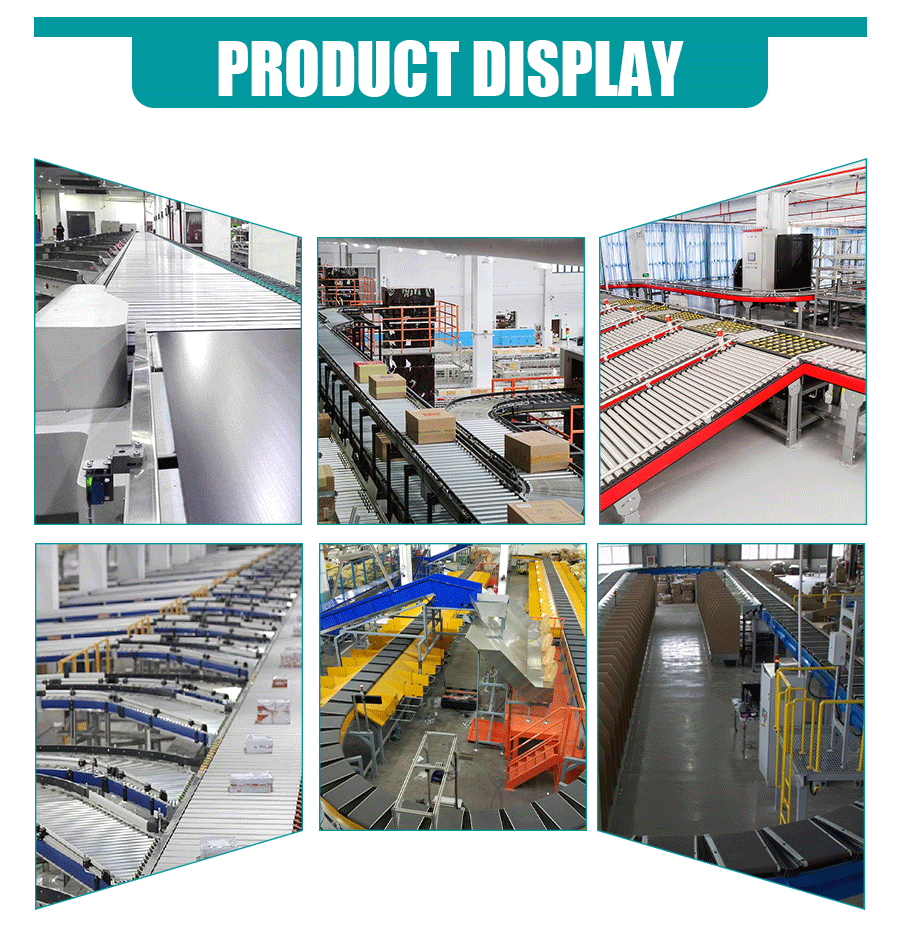

The sorting mechanism refers to the introduction of the automatic identification of the material into the main conveyor line of the sorting machine, and then the material through the sorting mechanism to the designated location. The sorting mechanism is the core equipment of sorting system.

The role of the main conveying device is to transport the material to the corresponding sorting crossing, in order to carry out follow-up operations, mainly by all kinds of conveying machinery, also known as the main conveying line.

Pre-processing equipment is the sorting system to the main conveying device to transport the sorting material into the feed platform and other auxiliary transport and operation platform. The feeding platform has two functions. One is that the operator uses the input device to send the destination address of each sorting material into the sorting system as the sorting operation instruction of the material. The second is to control the time and speed of sorting materials into the main conveying device to ensure that the sorting mechanism can accurately carry out sorting.

The sorting crossing, also known as the shunt conveyor line, is the channel that separates the material from the main conveyor line to enter the corresponding cargo collection area. Generally by steel belt, conveyor belt, roller and other components of the slide, so that the material from the conveying device to slide into the buffer table, and then warehousing operation or distribution work.

|

Name |

Automated Sortation Conveyor |

|

Length |

20000-24000mm or customized upon request |

|

Width |

2000mm or customized upon request |

|

Color |

Customized upon request |

|

Material |

carbon steel, stainless steel |

|

Feature |

Heat resistance, wear resistance, burning resistance, oil resistance, alkali resistance, alkali resistance, heat resistance, cold resistance, etc. |

|

Processing |

cutting, polishing, etc. |

|

Surface |

available upon request |

|

Quality Inspection |

We have QC for testing or customer inspection / accept 3rd party inspection |

|

Packaging |

1, standard seaworthiness, wooden box packaging, pallet packaging, etc. 2, according to customer requirements packaging. |

|

Export to |

USA, Australia, Brazil, Canada, Peru, Iran, Italy, India, Britain, Arabia, etc.。 |

|

Price term |

EXW,FOB,CIF,CFR,CNF,etc. |

|

Payment |

Western Union,T/T,L/C,etc. |

|

Certificates |

TUV&ISO&GL&BV,etc. |